Air-Blowing Optical Fiber Cable (ABF)

HRI

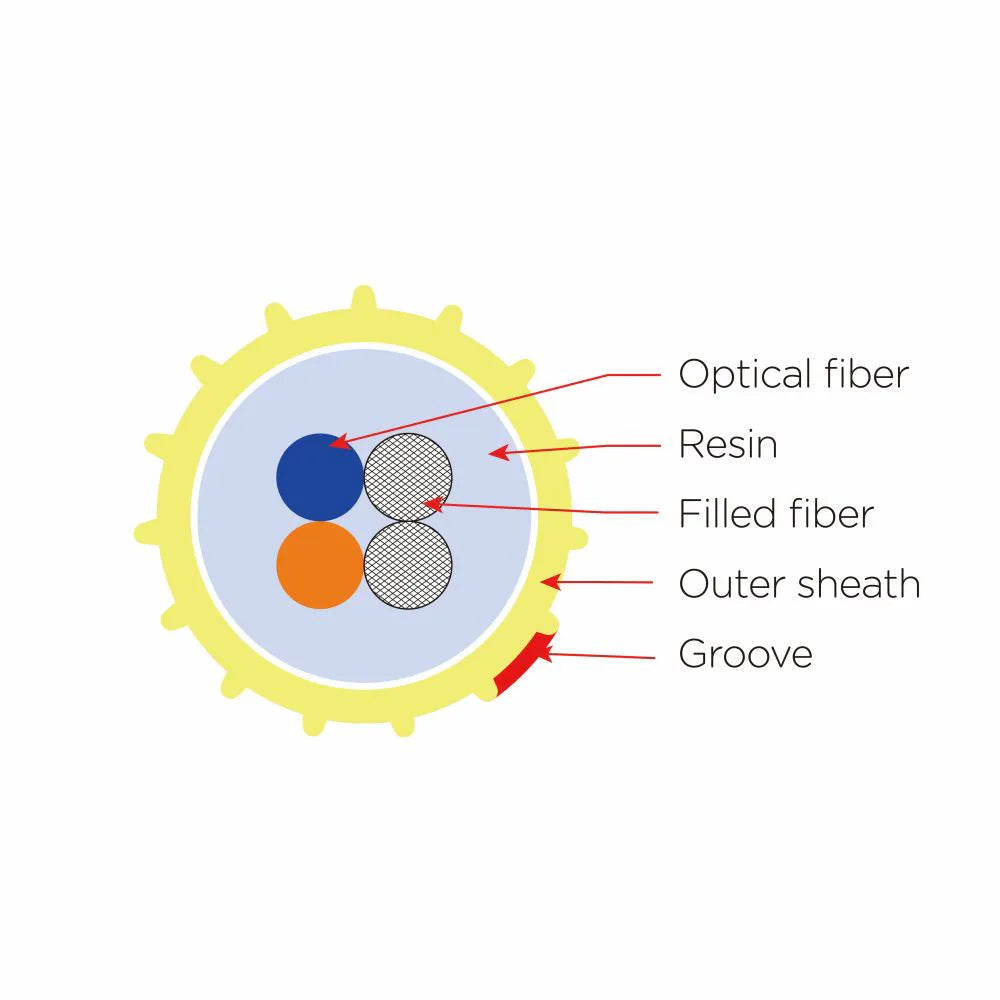

Enhanced Performance Fiber Optic Unit (EPFU) air-blown ultra-thin fiber optic cable

Air-blown micro cables use air-blown laying methods to connect optical branch points and user access points. The optical cable has good mechanical and temperature properties, high tensile strength guaranteed by fiberglass, good flexibility, easy construction, and low cost.

HRI

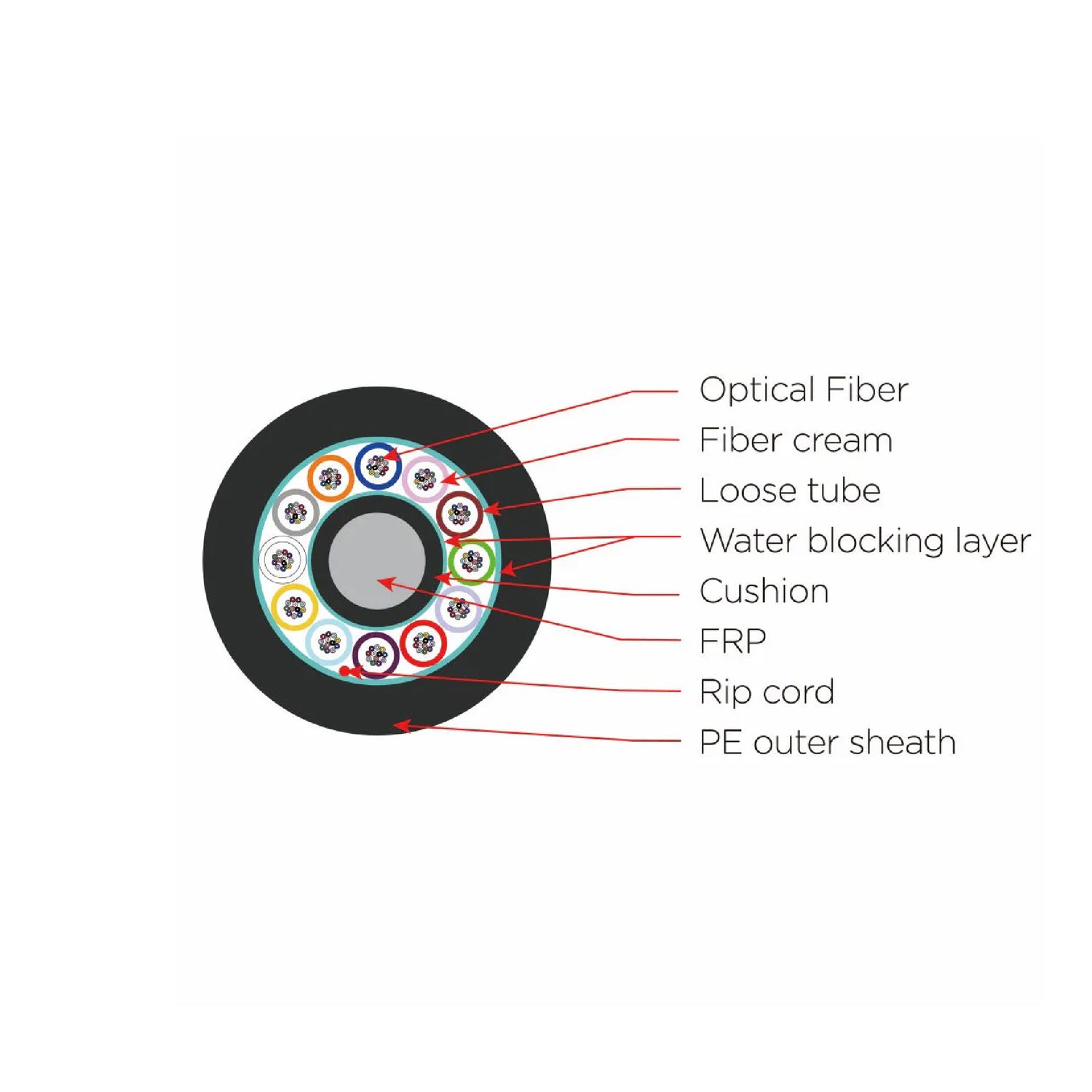

Conventional central tube air-blown micro cable (2-24 cores)

Air-blown micro cables use air-blown laying methods to connect optical branch points and user access points. The optical cable has good mechanical and temperature properties, high tensile strength guaranteed by fiberglass, good flexibility, easy construction, and low cost.

HRI

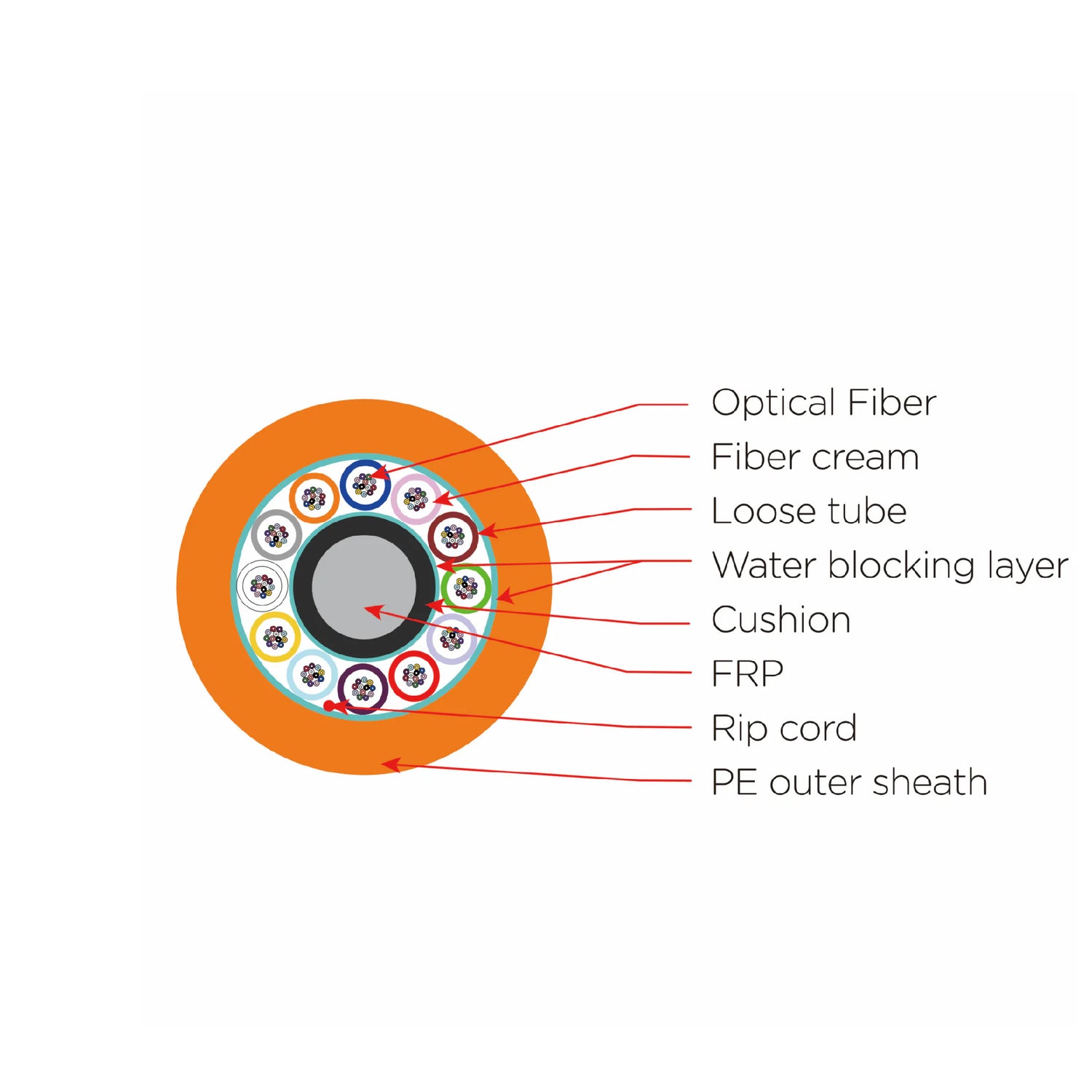

Layer-stranded PE sheathed air-blown micro cable (24-288 cores)

Air-blown micro cables use air-blown laying methods to connect optical branch points and user access points. The optical cable has good mechanical and temperature properties, high tensile strength guaranteed by fiberglass, good flexibility, easy construction, and low cost.

HRI

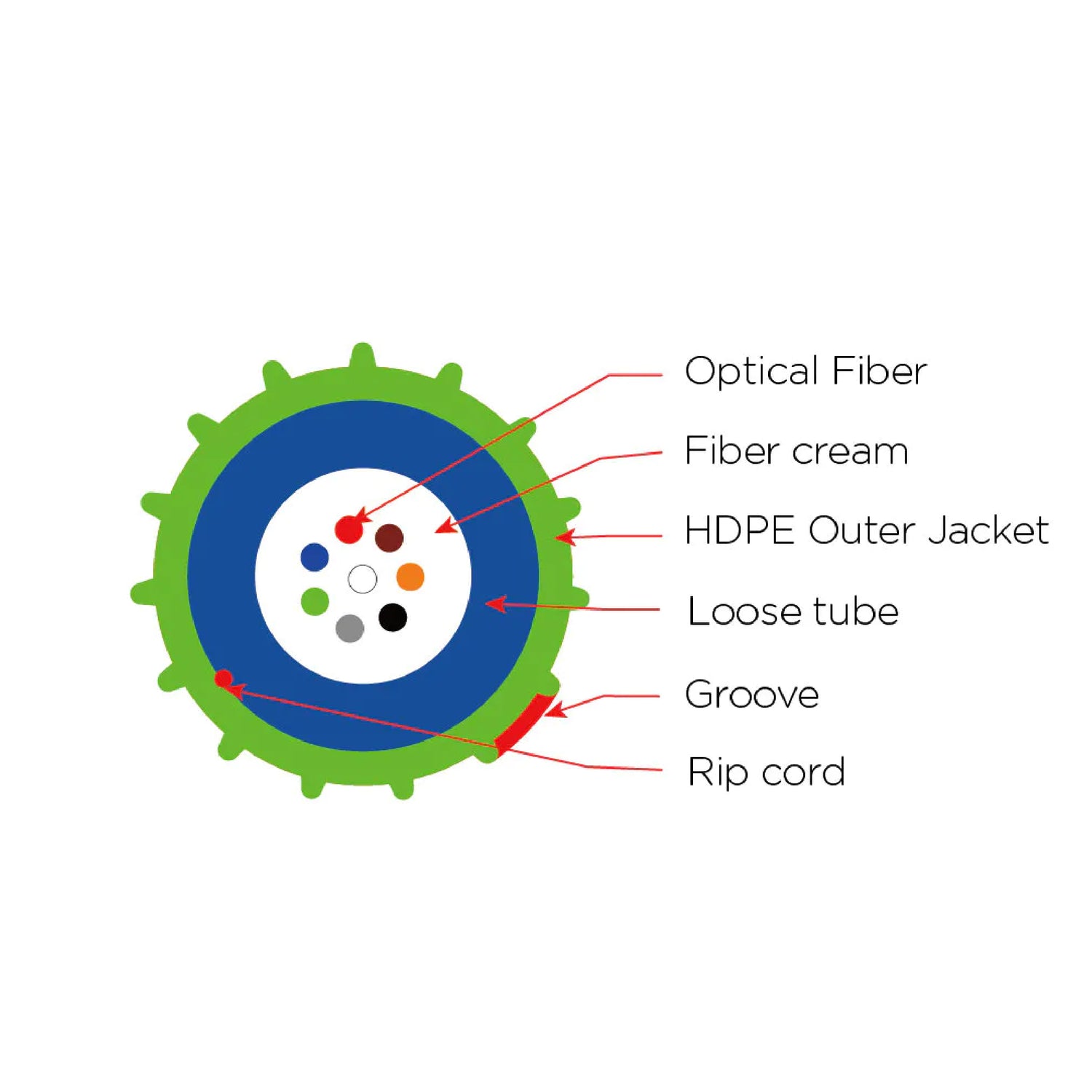

Layer-twisted nylon sheathed air-blown micro cable (24-288 cores)

Air-blown micro cables use air-blown laying methods to connect optical branch points and user access points. The optical cable has good mechanical and temperature properties, high tensile strength guaranteed by fiberglass, good flexibility, easy construction, and low cost.

HRI

Mini 2-24 Cores Air-blowing Micro Optical Fiber Cable

Air-blown micro cables use air-blown laying methods to connect optical branch points and user access points. The optical cable has good mechanical and temperature properties, high tensile strength guaranteed by fiberglass, good flexibility, easy construction, and low cost.